Recovering of pure oil after the oil sludge processing

OIL SLUDGE PROCESSING AND REFINING FACILITIES. INVESTMENTS

OUR SERVISES

OIL SLUDGE PROCESSING

OIL SLUDGE PROCESSING

BIO Energy Holding performs oil sludge processing at the client’s site worldwide. The quality of the processing conforms to ecostandards of Russian Federation and EU.

In order to perform works in Russia and Europe the company has licenses for collection, usage, neutralization, transportation and placement of the wastes of III-IV classes of hazard.

OPERATION OPTIONS

Oil sludge processing at the client’s site with factual separation of fractions into the refined petroleum product, mechanical impurities and water.

The quality of recovered petroleum product (processing result):

- content of mechanical impurities – up to 0.2 -1% of the volume of the petroleum product

- content of water, including molecular water, - up to 1-2%

PROCESSING COSTS

The cost of works of the oil sludge processing depends on different factors in total, such as: terms of the execution of works, conditions of the site, etc. The end product plays a significant part in the pricing of works. If works are performed at the client’s site, where the recovered petroleum product is returned back to the client after the treatment, the processing cost is assigned upon the actual fact of processing per 1mЗ.

partners

INTERNATIONAL DEVELOPMENT PROSPECTS

- The organization of joint enterprises with participation of regional partners for

major oil sludge processing market coverage

in the world - Attracting investors to regional projects with the given oil sludge processing market size

DEVELOPMENT STRATEGY

Producing 1 kit of mobile facilities for processing more than 72 ОООmЗ of oil sludge per year

PROJECT OBJECTIVES

Processing of oil sludge in order to get marketable petroleum product

To supply the facilities to the processing sites

Manufacturing of industrial facilities and concluding contracts

Development of a release version of the technology for customers’ needs (petroleum companies). Building a laboratory plant for the demonstration of technology

INTERACTION WITH PARTNERS

Regional partner contributes partial cost of the facilities

BIO Energy Holding provides the processing market, and/or regional partner works on their own sites

BIO Energy Holding together with the Finnish company and selected partner have ≈ equal share in the project, the technology is provided for usage at the prime cost of the technological process and the required chemical agent

A partner is to provide technical support and controls the performance of the facilities in the selected region

INTERACTIONS WITH INVESTORS

The investment in the facilities is no less than 600 000€

Investments in manufacturing of the facilities and the organizations of regional partners

A regional partner is granted up to 40% of the company’s stock with specified processing market at a term no less than 1 year

A regional partner has the right to withdraw stock capital after 12 months from the date of contribution or remain in possession of the company.

The terms are stipulated individually

BUSINESS ATTRACTIVENESS

HELPING THE PLANET

Our business helps the planet to breathe freely by solving the urgent environmental problem and eliminating the oil sludge "lakes"

GOVERNMENT APPROVAL

Worldwide support from government authorities, including GreenPeace

PROFITABLE BUSINESS

Great oil demand makes our business extremely profitable

FIGURES IN BRIEF

The official market of the processing industry in the world is about 58 billion euro, according to the unofficial data it is considerably larger

The facilities are processing 30-50 m3 of sludge per hour. The amount can be increased, if necessary...

For the period from 2016 our company has tentative agreements for processing more than 0,5 million m3 / in the world

The prime cost of processing with our technology including all expenses is at max 25 euro/mЗ

The cost of marketable oil after the processing (treatment) of fractions is on average 107€ per ton

BUISNESS SRTRUCTURE

Proprietor of the technology and manufacturer of the facilities

Prime contractor and representative of the technology. Has exclusive rights to the technology

We are looking for partners all over the world. You can become our partner in the following countries

EXPENDITURE AND SELLING PATTERN

FACILITIES

OUR TECHNOLOGY

A comprehensive analysis of analog facilities all over the world was carried out. All the weak points of different manufacturers were taken into consideration, and a practically flawless from technological point of view solution was developed. All analogs operate on mono- horizontal reactors, and in case of a breakdown the whole operational process will stop. The contamination operational range is very small, that results in clogging of the main unit. Moreover, these facilities are much more expensive.

A comprehensive analysis of analog facilities all over the world was carried out. All the weak points of different manufacturers were taken into consideration, and a practically flawless from technological point of view solution was developed. All analogs operate on mono- horizontal reactors, and in case of a breakdown the whole operational process will stop. The contamination operational range is very small, that results in clogging of the main unit. Moreover, these facilities are much more expensive.

Our solution is versatile and comprises 6 horizontal reactors. If any of it shuts down, the other 5 will function, with a slight performance decrease. Moreover, our contamination range is not limited. We deal with contamination of any sort, that is achieved due to the operation of 2 modules (of rough and light refining), which in turns remove the whole range of contaminations. As a result, we recover technically pure soil, water and petroleum product, which can be handed over to petroleum refinery.

The facilities are a mobile complex, which is transported in a 40-ft maritime container. The unbinding of all knots takes up to 7 days.

PROCESSING TECHNOLOGY

An oil sludge lake is usually about 200 ООО mЗ large. Oil sludge consists of compounds of the fuel and oil of different types, which also contains molecular water and mechanical impurities.

During the heating process of the solid oil sludge it alters its properties. Then, after adding the chemical agent, solid particles and molecular water are separated in the reactor.

The oil sludge processing end product is a marketable petroleum product (molecular content of water is up to 2%, solid substance up to 1%)

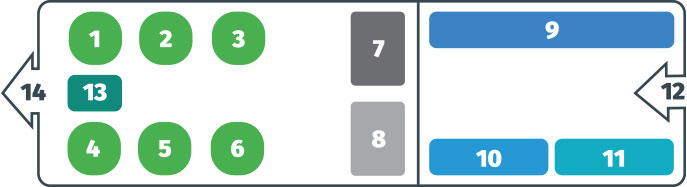

FLOW DIAGRAM OF FACILITIES

- 1-6

Reactors

- 7

Suction-pump of rough refining module. For oil sludge or heavy contaminated water. Performance 70m per hour Inlet / outlet - 3

- 8

High-pressure pump for sludge and soil scouring. Pressure hoses, outlet - 2”. Performance – 50 m per hour

- 9

Generator

- 10

Inlet for the treated emulsion from the intake module

- 11

Flowmeter

- 12

End product outlet

- 13

Tank with chemical agents

- 14

Compressor

SPECIFICATIONS

| parameter | unit | value | note |

|---|---|---|---|

| Performance | m3/hour | 30-50 | depends on the fraction |

| Power consumption | kW | 18-20 | |

| Weight of facility | kg | 20 000 | |

| Max size of impurities | mm | 150 | |

| Max content of mechanical impurities | % | not limited | primary filtration |

| Max content of water in sludge | % | not limited | |

| Max content of petroleum product | % | not limited | |

| Application of chemical agents | g/m3 | < 100 | |

| Fluid substance operation | yes | ||

| Solid substance operation | yes | ||

| Operating temperature of facility | °C | -18...+40 | до -60°С (OPTION) |

BASIC DATA

BIO Energy Holding Ltd offers Finnish technology and oil sludge processing and refining facilities. The performance of the Finnish facilities does not depend on the type or fraction of the oil sludge. Oil sludge is waste products of oil extraction or petroleum product processing. It is assumed that oil sludge comprises about 5% per year of the turnover of oil industry. The existing processing technologies have high costs and are limited to different factors, for example, they work with a certain type or fraction of oil sludge. The technology development strategy of BIO Energy Holding is to build a network of service companies of oil sludge processing in order to work at the international market. BIO Energy Holding offers the investors and clients a mutually beneficial cooperation in the industry of dealing with the environmental issue of petroleum waste disposal.

GENERAL FACTS

01

Oil sludge comprises 5% of the produced and sold petroleum and petroleum products, that is 800 million tons of oil, as all over the world it is extracted 4,2 billion tons of oil a year

02

The market of oil extraction and processing is constantly expanding. Alternative technologies have high costs and low performance

03

The amounts of oil sludge in the world are increasing for 6% per year, that is 350 million tons. (The spills of oil and petroleum products)

WHY FINLAND?

-

High level of patentee’s assertion

-

Finland pays special attention to environmental issues

-

Great possibilities for the technology development at the international and EU market

-

High quality at a reasonable price

WHY BIO ENERGY HOLDING?

The developed facilities differ from analogs in low prime cost and the processing efficiency

Service marketing outlets all over the world provided for 5-8 years at least, negotiations with other countries

High financial responsibility and stability of our clients – international oil companies

WHY OIL SLUDGE?

Oil sludge is a combination of physicochemical mixture, which consists of oil or petroleum products, solid substances (clay, oxides of metals, sand) and water

This waste type is highly hazardous to environment and is to be disposed or processed for further usage

Oil sludge processing and disposal is an urgent economical and environmental issue.